E-mail: info@aarealmachine.com

Mobile: +86-156 3736 1027

Fax: +86-373-3988367

WhatsApp: +86-156 3736 1027

Gyratory screen is used for high precision and large-capacity screening for 40 μm~10mm granules. It can be used in the screening of thousands of materials such as salt, sugar, soda ash, silica sand, ceramsite sand, urea, glass beads, alumina, clay, limestone, flour, milk powder, coffee, cereal, spices, cocoa powder, glucose, starch, ammonium nitrate, phosphate, potassium hydroxide, wood chip, flaking, wood powder, medicines, plastic granule, metal powder and so on.

1. Balanced operation, strong structure, durable and continuous operation and low failure rate.

2. Super large capacity (2~150 t/h). And the screening accuracy is as high as 90-99%.

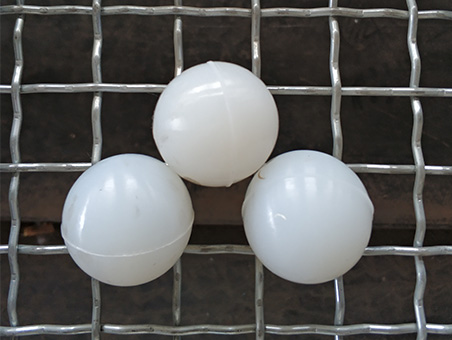

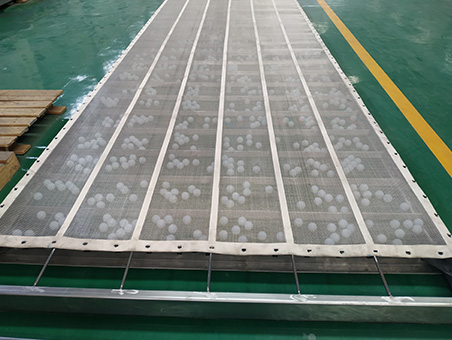

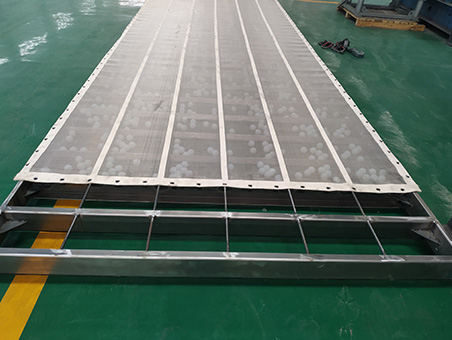

3. Use the bouncing balls to clear the screen and prevent the mesh from blocking effectively.

4. The screen is only loaded in the vertical direction and does not vibrate. The service life of screen is 5-100 times that of ordinary vibrating screen.

5. The three kinds of clips for tensioning screen are easy to disassemble and the replacement of the screen is convenient. The screen mesh is tightened automatically. The top cover is installed with self-adjusting clamps to realize quick disassembly and assembly.

6. Applied to 10mm to 40μm particle grading, up to 4 layers of screens. Can also use a mesh for duplex screening.

7. The whole machine runs smoothly. It can be mounted by seat or suspended.

8. Fully enclosed structure, no dust, noise below 80 decibels.

The gyratory reciprocating motion of gyratory screen begins with a circular motion at the feed end, gradually diminishing along the length of the machine to elliptical movement in the middle, and finally to an almost straight-line motion at the discharge end.

1.At the feed end: Circular Motion

The gyratory movement at the feed end can quickly complete the material’s spreading, stratifying, separating and moving forward across the full width of the screen surface.2.At center: Elliptical Motion

The long-stroke elliptical movement can enhance material stratification, which help to improve the screening capacity.3.At the discharge end: Reciprocating Motion

The reciprocating motion at the discharge end can remove the near-size particles, improving the screening efficiency. And it has almost no particles jump vertically, which ensures that the material is in constant contact with the screen surface.| Model | Screen Area (m²) | Layers of Screen | Power (KW) | Ref. Dimensions (mm) |

| AD-515 | 0.75 | 1~2 | 1.5 | 3050*766*1500 |

| AD-1021 | 2.1 | 1~2 | 3 | 3900*1310*1800 |

| AD-1030 | 3 | 1~4 | 4 | 4900*1310*1800 |

| AD-1036 | 3.6 | 1~4 | 4 | 5500*1310*1800 |

| AD-1530 | 4.5 | 1~4 | 5.5 | 4900*1958*2100 |

| AD-1536 | 5.4 | 1~4 | 5.5 | 5500*1958*2100 |

| AD-1836 | 6.48 | 1~4 | 7.5 | 5500*2238*2100 |

| AD-1840 | 7.2 | 1~4 | 7.5 | 5900*2238*2100 |

| AD-2050 | 10 | 1~4 | 11 | 6800*2500*2100 |

Motor

Exciter

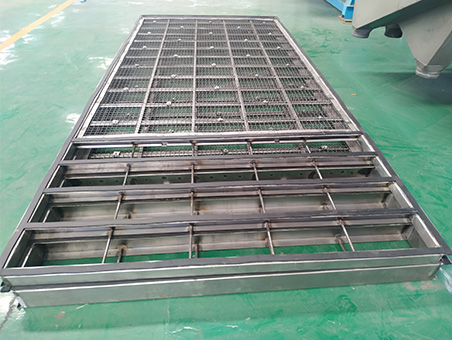

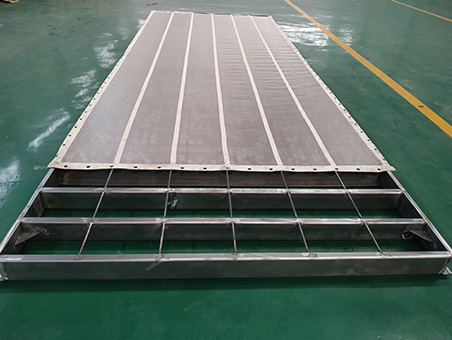

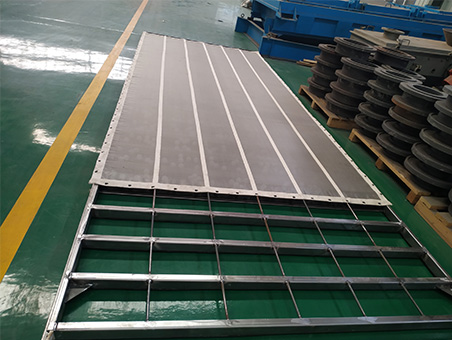

Ball Deck (woven wire mesh)

Ball Deck (perforated plate)

Compensating Clamps

Pulley

Clips 1

Clips 2

Clips 3

Grommet Screen

Mesh Cleaning Balls

1st Layer Screen Frame

2nd Layer Screen Frame

3rd Layer Screen Frame

4th Layer Screen Frame

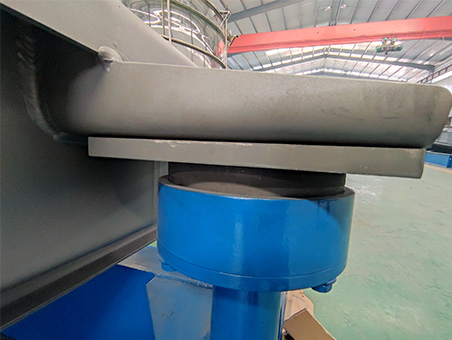

Graphite Support Block

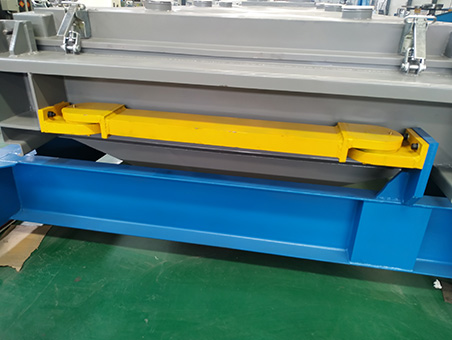

Drag Link

Suspension Cable

1. Seat Installation:

As the driving system of this machine has a balance function, outward transmitting force is smaller, it can be installed directly on the ground, or steel structure frame or platform that allow vibration.

Direct Discharge Type

Forward Type

2. Cable Suspension Installation:

The sieving machine can be hoisted by cables from the four corners of the machine to insulate the balance force of the sieving machine from the surrounding structure.

Direct Discharge Type

Forward Type

Abrasive: glass beads, slag, alumina, sand and other abrasive materials

Animal feed: feed powder and chips, meat paste and small food

Carbon products: coking coal, graphite, charcoal etc.

Chemical products: hundreds of different compounds

Clay: product classification

Fertilizer: raw material sieving and finished product fine screening. Including ammonium nitrate, phosphate, potassium hydroxide, urea and other compounds

Food: sugar, flour, milk powder, coffee, cereals, rice, nuts, condiments, cocoa powder, glucose, starch etc. Grain cleaning: corn, wheat, soybean and other cereals peeling and cleaning Ore: ore, rubble, limestone, soda ash and salt

Paper: paper pulp, coating

Fiberboard: wood chips, flaking, bits of wood, to make high quality fiberboard

Drug: many large drug manufacturers use AAREAL screening machines, which meet the health standard design, to achieve precise and effective separation and cleaning

Plastic: plastic particles, plastic powder

Powder metal: aluminum, copper, iron, nickel, steel, zinc and many other metal powders Recycling of resources:used in the recycling of various materials, such as PET recycling etc.

Steelmaking: classification of steel shot and metal filing

Copyright © Xinxiang AAREAL Machine Co.,Ltd All Rights Reserved Power by SinoArt