E-mail: info@aarealmachine.com

Mobile: +86-156 3736 1027

Fax: +86-373-3988367

WhatsApp: +86-156 3736 1027

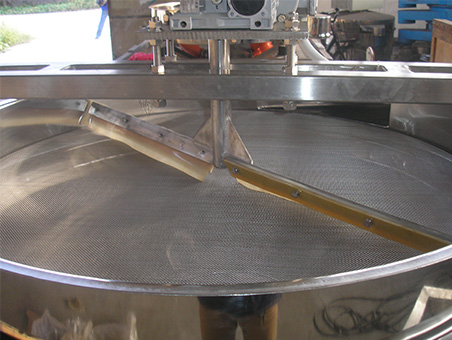

Tumbler screen is used for the large-capacity fine screening of 25 μm~1mm powder, which is comparable to German screening technology. It is applicable to chemical industry, food and spices, plastics and synthetic resin, mining, medicine, wood, metallurgy, feed, fertilizer, firework etc.

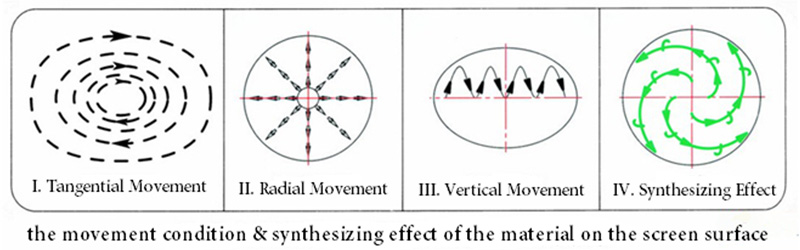

1. Simulate the action of manual screening. Particles are rolling and spiral involute. The screening accuracy is as high as 90-99.9%.

2. A variety of anti-blocking mesh technology (bouncing balls, rolling brush, air-brush, elastic scrape, ultrasonic etc.) ensure the continuity of screening.

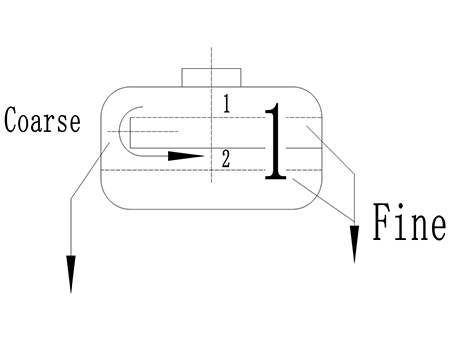

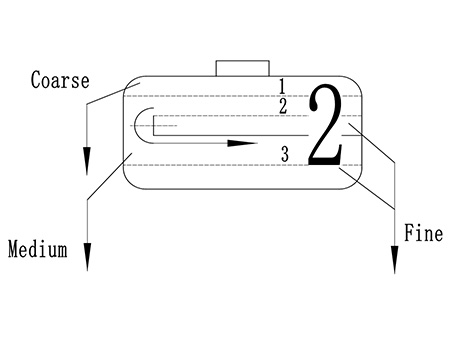

3. It can be used up to 7 layers for 8 particle sizes.

4. The soft screening action does not damage the particle structure of the material.

5. It is not easy to generate static electricity. Suitable for screening flammable, explosive and electrostatic materials.

6. Completely balanced. Super long operating time without failure.

7. Large sieve machine is equipped with cylinder lifting device, which is more convenient to replace the screen.

8. Circular block structure, simple disassembly, fully enclosed, more environmentally friendly.

9. The screen structure is diverse. It can be spliced together and also can be bonded as a whole.

10. The outlet can be rotated 360 degrees at will. And the noise is as low as 75dB.

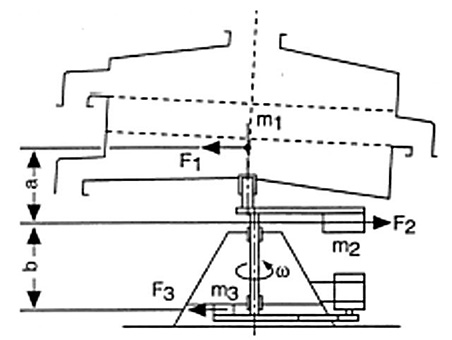

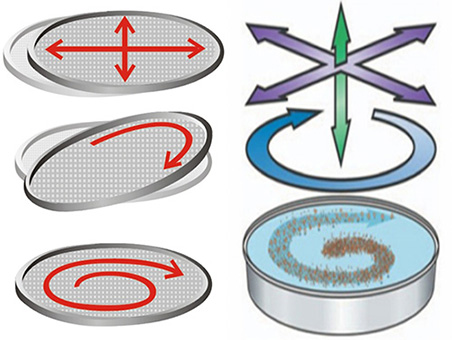

The tumbler screening machine utilizes the humanoid screening principle. To imitate the movement of artificial screening action and do three-dimensional circular motion, skillfully combine the sieving (planar circular motion) and winnowing (upward parabolic motion), establish horizontal and throwing three-dimensional tumbling movement, make the material on the screen surface appear involute spiral movement. The material takes a relatively long distance across the relative area, and the stay time on the screen of the material is more than 85%, improving the passing rate. The screening accuracy is as high as 90%~99%, increasing the yield.

BALANCE IS IMPORTANT !!

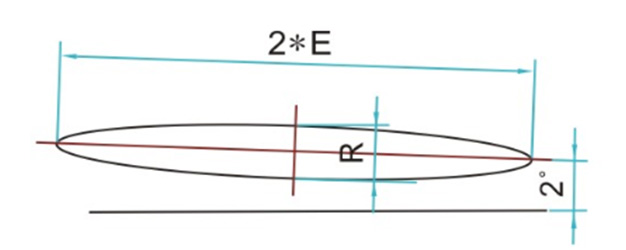

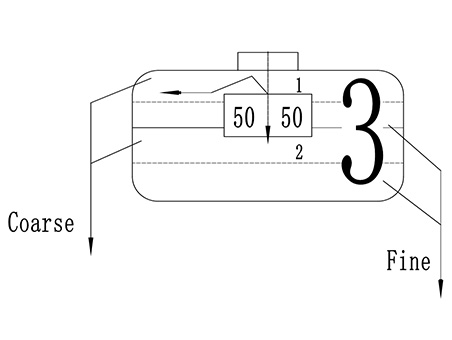

According to the physical properties of the material and the different screening requirements of customers, we can adjust the independent and adjustable rotate speed, eccentricity, radial force, tangential force, so as to change the material stay time on the screen surface and the moving route to achieve the best screening effect.

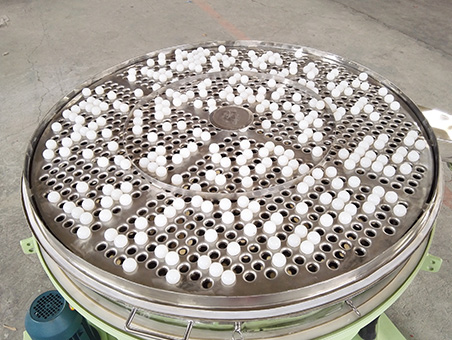

The anti-blingding technology is advanced and diverse. Different cleaning methods can prevent the screen holes from clogging and ensure the continuity of screening.

Bouncing Ball Cleaning

Ultrasound Cleaning

Brush Cleaning

Air Jet Cleaning

Combined Air Jet and Brush Cleaning

Scraper Cleaning

| Model | AM-600 | AM-1000 | AM-1200 | AM-1500 | AM-1800 | AM-2000 | AM-2300 | AM-2600 | AM-2900 |

| Screen Area (m2) | 0.28 | 0.72 | 1.10 | 1.80 | 2.30 | 2.60 | 3.90 | 5.30 | 6.40 |

| Layers | 1~5 | 1~5 | 1~5 | 1~5 | 1~5 | 1~5 | 1~5 | 1~5 | 1~5 |

| Power (KW) | 0.25 | 1.5 | 1.5 | 2.2 | 4.0 | 4.0 | 4.0 | 5.5 | 5.5 |

| Mesh Cleaning System | Optional: balls, brush, air jet, combined air jet and brush, ultrasonic system, scraper etc. | ||||||||

Only by recording the best operating parameters, can you reproduce the best operation and achieve the best screening results.

Date: Material: PVC Powder

Min-1 220

Radial Direction R 8

Tangent Direction T 2

Eccentricity E 35

(Double Screening) |

|

|

|

It can be widely used for screening milk powder, citric acid, xylitol, food additives, sugar, salt, yeast, glass beads, activated carbon, graphite, spherical proppants, aluminum oxide, silica sand, frac sand, ceramic glazes, clay, pigments, refractory material, calcium carbonate, limestone, fertilizer, urea granules, iron powder, rubber, resin, ABS, EPS, PAA, PVC, catalyst etc.

Copyright © Xinxiang AAREAL Machine Co.,Ltd All Rights Reserved Power by SinoArt