E-mail: info@aarealmachine.com

Mobile: +86-156 3736 1027

Fax: +86-373-3988367

WhatsApp: +86-156 3736 1027

3 greatest strengths of our AF model Gyratory Sifter compared to products produced by other Chinese suppliers in the market:

(1) The exciter can be disassembled and assembled as a whole, which is very convenient for repair and maintenance;

(2) The vibration exciter adopts high-quality bearings and running parts, and has a long service life;

(3) The material can be full of the whole screen surface, effectively using the screen area.

The gyratory sifter is widely used in large-capacity, multi-granularity screening of granular materials.

The screen side tensioning device, the ball cleaning system, and the largest horizontal amplitude make the screen passing rate reach the highest and get huge screening capacity. It is a new generation of screening equipment with low failure rate, low downtime rate, low operating cost, high productivity, high accuracy and high efficiency.

1. The full gyratory and balance movement make the material full of screen surface, and make better use of the screen.

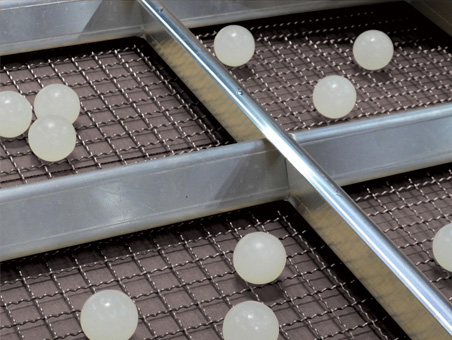

2. Ball cleaning system: use the bouncing balls to effectively clean the mesh. The effect of anti-blocking is good.

3. The horizontal amplitude is large enough to improve the sieving effect of near-size particles effectively, making the passing rate reach the highest.

4. The action frequency can be up to 300 times per minute, which makes a larger production capacity and a higher accuracy. High efficiency and energy saving.

5. It can be used up to 6 layers and get 7 kinds of particle sizes, to complete the screening of 12 mesh~325 mesh.

6. Various forms of compound screening can be completed, and the screen can be up to 12 layers, making the output larger.

7. It only takes 3 minutes to replace a screen.

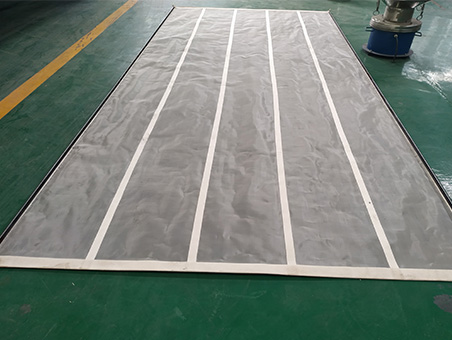

8. The screen tensioning system helps to maintain the screen tension and the screening efficiency.

9. Smooth and quiet operation, low noise, full closed, no dust flying, and environment friendly.

10. Strong structure, continuous operation and low failure rate.

1. Unique technology, the screen has no blind eye area.

2. The screen always keeps tension to make sure the screen mesh will not blind and ensure the screening effect.

3. The material is fully covered with screen, no deviation.

4. The power structure choose high-quality parts to ensure durability. The design of power structure is ingenious, convenient to replace the belt and maintenance.

5. CNC machining and riveting technology ensure the accuracy and uniformity.

side-tensioned screen design makes easy screen replacement

use bouncing balls to clean the screen mesh

The full gyratory movement quickly spreads, stratifies and separates the materials, and the horizontal and uniform rotation makes each area of the screen have the consistent screening action and efficiency, which improves the processing capacity of the machine and realizes large capacity and high efficiency screening.

The stroke, rotation speed and screen slope angle can be customized, and the stroke and rotation speed can be optimized on site to improve the screening performance for different products.

The rotating motion pushes the bouncing balls under the screen to continuously hit the screen, so that the wedged particles and near-size particles are ejected, keeping the screen clean. The large horizontal amplitude also effectively improves the screening effect of near-size particles. According to different applications, people can choose 50mm, 40mm or 30mm bouncing balls.

1. Rotation speed: 180~330 rpm, and can be fine-tuned

2. Range of Screen Slope: 3°~7°

3. Products: up to 12 screens, screening area: 3~73.5 square meters, can produce up to seven products

4. Adjustable stroke: 15~50mm

5. More designs:

Countercurrent screen: The discharge port is directly below the feed port, which is convenient for the connection of the system.

Compound screen: Multiple screens with the same mesh size can be combined on a sieve machine multiple times to complete multiple frequency screening at one time.

The screens can be up to 12 layers. And one screen mesh can be up to 6 composites, two screens can be up to 4 composites, three screens can be up to 4 composites, and four or five screens can be double composited, which makes the output larger, to achieve the effect of one compound screener is equivalent to multiple ordinary single-frequency screener.

| Layers | Model | Screening Area for Single Layer (m2) | Power (KW) | Frequency (r/min) | Dimension (mm) |

| 1~6 | AF-1025 | 2.5 | 3 | 180~330 | 3400*1700*2000 |

| AF-1030 | 3 | 3 | 3900*1700*(2000~3600) | ||

| AF-1036 | 3.6 | 3 | 4500*1700*(2000~3600) | ||

| AF-1230 | 3.6 | 4 | 3900*1900*(2000~3600) | ||

| AF-1236 | 4.3 | 4 | 4500*1900*(2000~3600) | ||

| AF-1530 | 4.5 | 5.5 | 3900*2200*(2000~3600) | ||

| AF-1536 | 5.4 | 5.5 | 4500*2200*(2000~3600) | ||

| AF-1830 | 5.4 | 7.5 | 3900*2500*(2000~3600) | ||

| AF-1836 | 6.48 | 7.5 | 4500*2500*(2000~3600) | ||

| AF-2030 | 6 | 7.5 | 3900*2700*(2000~3600) | ||

| AF-2036 | 7.2 | 7.5 | 4500*2700*(2000~3600) | ||

| AF-2040 | 8 | 7.5 | 5100*2700*(2000~3600) |

Note: The data above is for reference only. Our company reserves the right to modify.

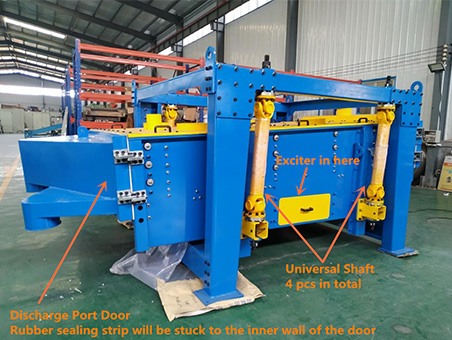

Universal Shaft, Discharge Port Door

Access Door, Motor, V-belt

Ball Deck, Balls, Sealing Strip

Rubber Sealing Strip

Hook Screen

Exciter

The gyratory sifter is widely used in different applications in many industries, such as chemical industry, mining, quarrying, potash, coal, clay, animal feed, rubber, glass, plastic pellets, wood flour, metal recycling and chemicals, cereal, peas , soybeans, corn, beans, wheat, barley, rape and hulling operations. Especially suitable for the most demanding screening requirements such as silica sand, frac sand, ceramic proppant, activated carbon, chemical fertilizer, limestone, petroleum coke, plastic granules, polyvinyl chloride powder, salt, sugar and so on.

Copyright © Xinxiang AAREAL Machine Co.,Ltd All Rights Reserved Power by SinoArt