E-mail: info@aarealmachine.com

Mobile: +86-156 3736 1027

Fax: +86-373-3988367

WhatsApp: +86-156 3736 1027

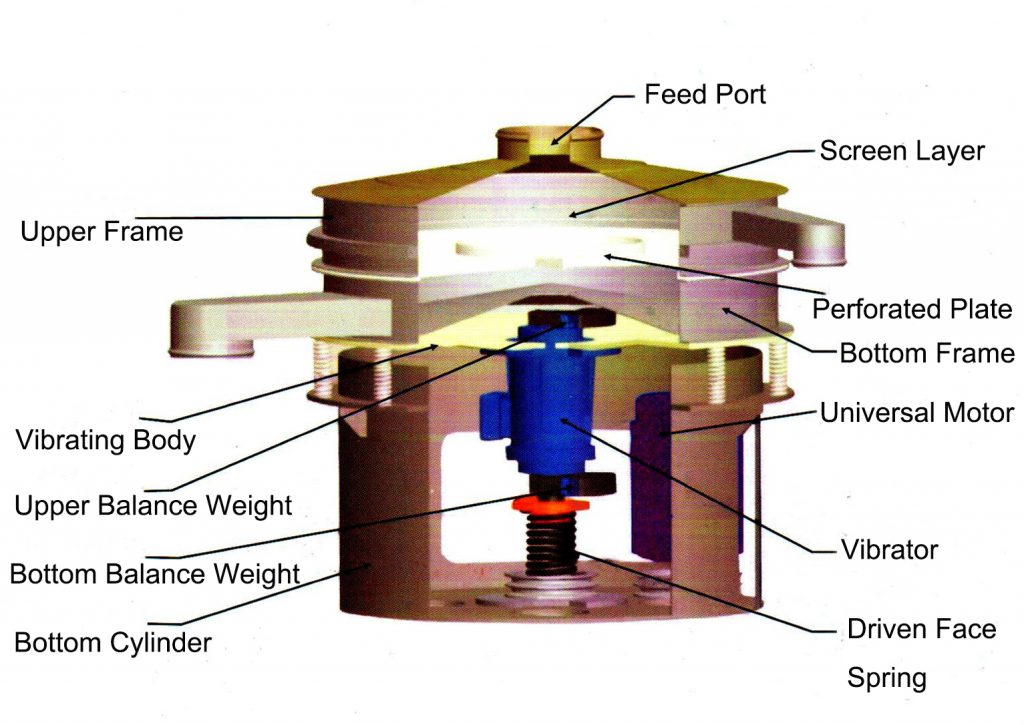

Our AYGO powerful vibrating screen does not use vibrating motor but instead use general-purpose motors, keeping the vibratory agent and motor separate.The upper and lower weights mounted to the top and bottom of the vibratory agent enable the three-dimensional movement (horizontal, verticle and oblique) and treatments according to the material properly.

The optimal adjustment of vibrations and revolutions is possible by integrating the inverter control to the machine.

Our AYGO series vibrating sieve machines meet the market demand for screening that is faster, more reliable and more precise. The doubling of amplitude achieves two to four times greater screening capacity than the conventional types. Moreover, the vibration pattern can be altered in accordance with the materials.

1. The longitudinal acceleration is twice as much as the original product rotary sieve (compared with our company).

2. The handling capacity is 2~4 times that of the original product (compared with our company). Materials those are difficult to screen can hardly clog up the mesh, and the output is also doubled.

3. The noise is obviously decreased. Small volume, convenient movement, no installation foundation.

4. With more powerful vibration force and solid structure.

5. More convenient to replace screen mesh.

6. Ordinary motor drive. Explosion-proof motor drive is also available.

The upper and lower weights mounted to the top and bottom of the vibratory agent enable the three-dimensional movement (horizontal, verticle and oblique) and treatments according to the material properly.

Generally, the machines vibrate with the screen surface as the center, and the weights mounted at both shaft ends of the vibratory agent creat the vibrations. The revolution of the upper weight generates horizontal vibrations to the screen surface and moves the materials fed onto the center of the screen in the direction of revolution. The lower weight generates vertical vibrations and moves the materials toward the periphery. These vibrations are combined to generate special three-dimensional movements at the screen. Shifting the phase of the upper weight in relation to the lower weight changes the vibratory behavior, thus creating the optimal movement for the materials being treated.

| Diameter (mm) | 500 | 800 | 1000 | 1200 | 1500 |

| Motor (KW) | 0.75 | 1.5 | 2.2 | 3.7 | 3.7 |

| Vibration Number | 1800 (V.P.M) | 1500 (V.P.M) | 1200 (V.P.M) | ||

| Material | Part contact powder: SUS304 Others: hot dip galvanizing on SS400 | ||||

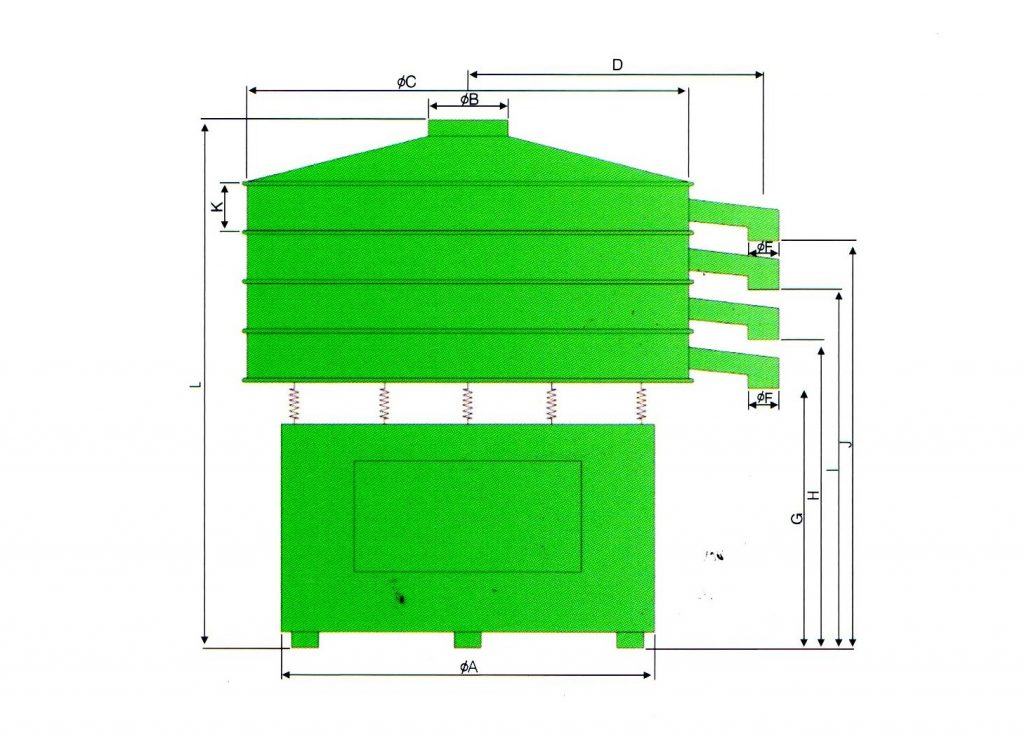

| Model | A | B | C | D | E | F | G | H | I | J | K | L |

| AYGO-500-1 AYGO-500-2 AYGO-500-3 | 550 | 100 | 490 | 375 | 80 | 80 | 438 | 542 | -- | -- | 100 | 723 |

| 647 | -- | 828 | ||||||||||

| 647 | 752 | 933 | ||||||||||

| AYGO-800-1 AYGO-800-2 AYGO-800-3 | 815 | 150 | 785 | 575 | 100 | 100 | 495 | 638 | -- | -- | 127 | 929 |

| 770 | -- | 1061 | ||||||||||

| 770 | 902 | 1193 | ||||||||||

| AYGO-1000-1 AYGO-1000-2 AYGO-1000-3 | 815 | 200 | 917 | 675 | 160 | 100 | 508 | 642 | -- | -- | 125 | 957 |

| 774 | -- | 1089 | ||||||||||

| 774 | 906 | 1221 | ||||||||||

| AYGO-1200-1 AYGO-1200-2 AYGO-1200-3 | 1030 | 250 | 1112 | 780 | 160 | 160 | 685 | 865 | -- | -- | 165 | 1200 |

| 1035 | -- | 1370 | ||||||||||

| 1035 | 1205 | 1540 | ||||||||||

| AYGO-1500-1 AYGO-1500-2 AYGO-1500-3 | 1030 | 250 | 1395 | 950 | 200 | 160 | 685 | 880 | -- | -- | 155 | 1236 |

| 1040 | -- | 1396 | ||||||||||

| 1040 | 1200 | 1556 |

Handling Capability Reference:

| Name | Specific Gravity | Particle Size (mesh) | Powerful Type | Ordinary Type | Capability Ratio | |||

| 1 | Chemicals | 0.5 | 400# 500# | AYGO-600-2S | 36Kg/h | AY-600-2S | 10Kg/h | 3.35 |

| 2 | Resin | 0.9 | 80# | AYGO-1000-1S | 660Kg/h | AY-1000-1S | 283Kg/h | 2.33 |

| 3 | Silicide Alkali | 1.3 | 60# | AYGO-1000-1S | 970Kg/h | AY-1000-1S | 800Kg/h | 1.21 |

| 4 | Silica | 0.9 | 100# | AYGO-1000-1S | 500Kg/h | AY-1000-1S | 280Kg/h | 1.79 |

| 5 | Processed Silica | 0.5 | 100# | AYGO-1000-1S | 32Kg/h | AY-1000-1S | 28Kg/h | 2.74 |

| 6 | Silica Sand | 1.5 | 35# | AYGO-1000-1S | 2000Kg/h | AY-1000-1S | 1000Kg/h | 2.00 |

| 7 | Pharmaceuticals | 0.6 | 14# 50# | AYGO-600-2S | 38Kg/h | AY-600-2S | 12Kg/h | 3.35 |

| 8 | Abrasive Material | 2.5 | 32# | AYGO-800-1S | 3700Kg/h | AY-800-1S | 560Kg/h | 6.60 |

Copyright © Xinxiang AAREAL Machine Co.,Ltd All Rights Reserved Power by SinoArt