E-mail: info@aarealmachine.com

Mobile: +86-156 3736 1027

Fax: +86-373-3988367

WhatsApp: +86-156 3736 1027

1. The structure is simple and compact, the lubrication point is less, and the lubrication point is not in contact with the material. No special installation requirements, therefore the installation is convenient and the maintenance workload is small.

2. The sealing performance is good when the closed type is used. Conveying dusty, toxic and volatile materials has no pollution to the environment, and it can realize multi-point feeding and multi-point discharging.

3. Due to the use of the resonance principle of mechanical vibration, the installation foundation is regarded as one of the mass points, the power consumption is low, and the power consumption is less than half of the screw conveyor with the same conveying length and productivity.

4. Because the material jumps forward with the parabolic trajectory during the transportation process, the conveyor trough wears slightly, and the service life is more than three times higher than that of the screw conveyor.

5. The operating noise is not greater than 75dB.

6. It can start frequently and operate continuously under the rated amplitude condition.

7. It is suitable for conveying requirements of longer distance and wider trough width.

Advantages:

1. High stiffness and simple structure, suitable for long distance and quick conveying.

2. The total height is low and suitable for limited space.

3. Multiple application can be achieved easily.

4. Single unit of conveyor length can reach 25 meters, and has been proved to be feasible.

5. Highly reliable, easier maintenance and lower cost.

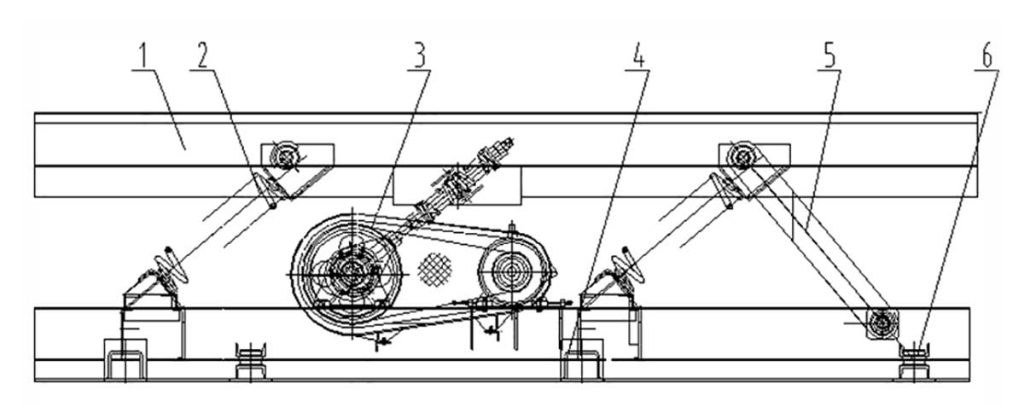

Structure:

1. conveyor trough 2. main vibration springs 3. drive connecting rod mechanism 4. base 5. guide rod 6. auxiliary support

| Model | Capacity (t/h) | Vibration Frequency (Hz) | Trough Length (m)/Power (KW) | |||||||||||

| 3 | 4 | 5 | 6 | 8 | 10 | 12 | 15 | 18 | 20 | 25 | 30 | |||

| ASL150 | 5 | 6.7~10.8 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 2.2 | 2.2 | 2.2 | 3.7 |

| ASL300 | 20 | 6.7~10.8 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 2.2 | 2.2 | 3.7 | 3.7 | 3.7 | 5.5 |

| ASL450 | 35 | 6.7~10.8 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 2.2 | 2.2 | 3.7 | 3.7 | 3.7 | 5.5 | 5.5 |

| ASL600 | 50 | 6.7~10.8 | 1.5 | 1.5 | 1.5 | 1.5 | 2.2 | 2.2 | 3.7 | 3.7 | 3.7 | 5.5 | 5.5 | 7.5 |

| ASL750 | 65 | 6.7~10.8 | 1.5 | 1.5 | 2.2 | 2.2 | 3.7 | 3.7 | 3.7 | 5.5 | 7.5 | 7.5 | 5.5*2 | 5.5*2 |

| ASL900 | 80 | 6.7~10.8 | 1.5 | 1.5 | 2.2 | 2.2 | 3.7 | 3.7 | 5.5 | 5.5 | 7.5 | 7.5 | 5.5*2 | 5.5*2 |

| ASL1050 | 95 | 6.7~10.8 | 1.5 | 2.2 | 2.2 | 3.7 | 3.7 | 5.5 | 5.5 | 7.5 | 7.5 | 5.5*2 | 5.5*2 | 7.5*2 |

| ASL1200 | 110 | 6.7~10.8 | 1.5 | 2.2 | 2.2 | 3.7 | 3.7 | 5.5 | 5.5 | 7.5 | 5.5*2 | 5.5*2 | 5.5*2 | 7.5*2 |

| ASL1350 | 125 | 6.7~10.8 | 1.5 | 2.2 | 3.7 | 3.7 | 5.5 | 5.5 | 7.5 | 7.5 | 5.5*2 | 5.5*2 | 7.5*2 | 7.5*2 |

| ASL1500 | 140 | 6.7~10.8 | 2.2 | 2.2 | 3.7 | 3.7 | 5.5 | 5.5 | 7.5 | 5.5*2 | 5.5*2 | 5.5*2 | 7.5*2 | 11*2 |

| ASL1650 | 155 | 6.7~10.8 | 2.2 | 3.7 | 3.7 | 3.7 | 5.5 | 7.5 | 7.5 | 5.5*2 | 5.5*2 | 7.5*2 | 7.5*2 | 11*2 |

| ASL1800 | 170 | 6.7~10.8 | 2.2 | 3.7 | 3.7 | 3.7 | 5.5 | 7.5 | 7.5 | 5.5*2 | 5.5*2 | 7.5*2 | 7.5*2 | 11*2 |

| ASL2000 | 185 | 6.7~10.8 | 2.2 | 3.7 | 3.7 | 5.5 | 5.5 | 7.5 | 5.5*2 | 5.5*2 | 7.5*2 | 7.5*2 | 11*2 | 11*2 |

Note:

1. The above data is for reference only. Our company reserves the right to modify the above data.

2. The conveying capacity here is calculated according to the horizontal transport of river sand (bulk density 1.6t/m³, water content 5%).

3. The power of the conveying trough with sealing cover, lining plate and conveying materials with different bulk densities needs to be recalculated.

4. When the conveying distance exceeds 15 meters, we will adopt the segmented structure, and the user needs to assemble and connect on site.

Single-mass connecting rod vibratory conveyor is suitable for power, coal, building materials, metallurgy, grain and other industries, which is used to complete the conveying process of powder and granular materials. It is suitable for fine powder materials that are difficult to transport, such as emery powder, fly ash, cement, carbon powder, coal powder etc., uniformly and continuously or quantitatively transported from the storage bin or funnel to the receiving device, which has superior conveying performance.

Copyright © Xinxiang AAREAL Machine Co.,Ltd All Rights Reserved Power by SinoArt