E-mail: info@aarealmachine.com

Mobile: +86-156 3736 1027

Fax: +86-373-3988367

WhatsApp: +86-156 3736 1027

Centrifugal sifter is also called rotary sifter etc.. It is used to sift and screen high volumes of material at high speed and with greater efficiency in comparison to other sifters.

This kind of screening machine solves the screening problem of materials with multi-fiber, large viscosity, static electricity and easy to adsorb, such as Chinese medicine powder, battery material, starch etc. The centrifugal sifter can also be constructed to be run under pressure or vacuum if it’s necessary for your application.

1. Small size, light weight, steady and no vibration, no noise, good sealing performance, no dust and high efficiency.

2. The shell structure is novel. Easy to control. Simple installation and low requirement for laying foundation.

3. It can be used by single machine or matching with multi-machines. Long time continuous operation. Safe and reliable.

4. The screen mesh is washed by the cyclone and can be automatically cleared. It can be equipped with a variety of material screens: stainless steel wire mesh, stainless steel or carbon steel punching hole mesh. Long service life. The nylon fiber screen has anti-static and automatic cleaning function.

5. Screening and crushing into one. It has the recrushing function to the caking material.

6. Without static electricity in the operation. The friction in the screening process is small. Not easy to produce static electricity.

7. This machine can be matched with the pneumatic conveying system, directly connected into the wind path, saving resources.

8. New design: The gas protection system can deliver the purified air to both ends of the equipment, which can effectively reduce the temperature produced by the equipment during operation. The gas isolation layer is formed on the bearing, thereby preventing dust from entering, effectively prolonging the service life of the bearing, reducing the maintenance frequency and improving the work efficiency.

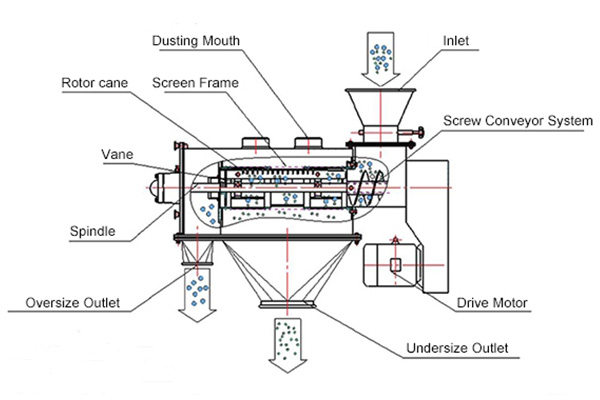

The machine is made up of motor, base, housing, material in and out propelling device, screen barrel etc.

When it works, the material enters from the feed inlet at the upper end of the housing, and the rotating screw feeds the material into the screen barrel.

Material into the screen barrel is driven by rotating scraper, impacting the cylindrical screen mesh under the action of centrifugal force and cyclone propelling force, making the material smaller than the mesh through the screen and discharge from the fine outlet.

The coarse powder is bounced back by the screen, moving forward and discharging from the coarse outlet under the action of cyclone propelling force and scraper, thus completing the entire screening process.

| Model | Material | Apply to |

| AL-18-65 | Q235A, SUS304 | < 500 mesh |

| AL-30-100 | Q235A, SUS304 | < 500 mesh |

| AL-50-130 | Q235A, SUS304 | < 500 mesh |

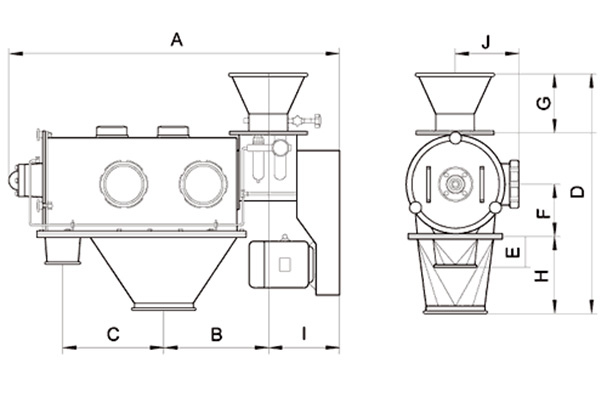

| Model | A | B | C | D | E | F | G | H | I | J |

| AL-18-65 | 1430 | 460 | 420 | 1005 | 135 | 230 | 250 | 330 | 340 | 210 |

| AL-30-100 | 1845 | 655 | 766 | 1240 | 320 | 285 | 300 | 350 | 380 | 290 |

| AL-50-130 | 2230 | 870 | 790 | 1775 | 280 | 515 | 150 | 660 | 400 | 485 |

Note: we can design and manufacture special type of sieving machine according to user's requirement.

The centrifugal sifter is used for sieving materials of sticky, static and multi-fiber. Applicable to metallurgy, mining, pharmaceutical, food, chemical, metal powder and non-metal industries etc.

Such as Chinese medicine powder, battery material, starch, glucose powder, xylitol, soybean protein, peanut protein, vitamin C, sorbitol, ganoderma lucidum powder, malt powder, coffee powder, bread powder, flour, condiments, food additives, traditional Chinese medicine powder, APIs, pharmaceutical raw materials, active pharmaceutical ingredients, pharmaceutical intermediates, glass beads, perlite, silicon carbide, silicon powder, activated carbon, epoxy resin, polyethylene powder, fire extinguishing agent, zircon powder, pigment (phthalocyanin blue, phthalocyanin red, phthalocyanin yellow, yellow lead, high sand ceramic pigments etc.), magnetic material, drill powder, pyrophyllite powder, barium sulfate, lithium manganese oxide, zinc borate, coal ash, silicon powder, glaze, powder coating, pollen, dehydrated vegetable, egg powder, milk powder, soda powder, essence, magnesium oxide, magnesium hydroxide, calcium oxide, silicon nitride, alumina, molybdenum disulfide, cellulose, nanograde titanium dioxide, PVC resin powder, barium sulfate, silica gel powder, guar bean gum, calcium fluoride and other powder materials.

Copyright © Xinxiang AAREAL Machine Co.,Ltd All Rights Reserved Power by SinoArt