E-mail: info@aarealmachine.com

Mobile: +86-156 3736 1027

Fax: +86-373-3988367

WhatsApp: +86-156 3736 1027

Linear vibrating screen is also called rectangular separator, horizonal vibrating screen, rectangular vibrating screen, rectangular sifter, rectangular screener, linear screen etc.

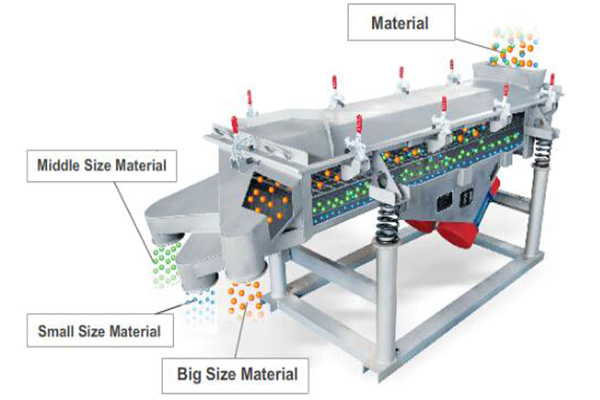

Driven by two vibration motors, the linear vibrating sieve does rectilinear vibration. By adjusting the installation angle of the vibrating motor, the material throwing angle can be changed to achieve the required form of production. Since the rectangular separators make materials produce a very large acceleration, it can meet the high production demand.

This machine is usually installed horizontally and can be also installed with elevation or downtilt to meet different production requirements.

1. Suitable for the rough screening operation of high capacity.

2. Various kinds of screen structures (wooden frame, metal frame, end-tension screen etc.).

3. Quick-open clamps can be used to remove easily.

4. The screen surface angle can be adjusted to balance the screening accuracy and production capacity.

5. The high quality damping rubber spring can be used to minimize the noise, and reduce the large swing of the start stop in the same time.

6. The motor can be installed below or above or side of the screen box to adapt to different environments.

7. It can be installed 1~8 layers of screens, and adopts the bouncing ball to clear screen.

8. Completely enclosed structure, no dust.

The rectangular separator is driven by dual vibrating motors. When the two vibration motors do synchronized and reversed rotation, the vibration force generated by its eccentric block offset each other parallel to the direction of the motor spindle, superimposing as a resultant force perpendicular to the direction of the motor shaft, thus the movement trajectory of the screening machine is a straight line.

The two motor shafts have an angle of dip in the vertical direction relative to the screen surface. Under the combined effect of vibration force and material self-gravity, materials in the screen surface do jumping movement, so as to achieve the purpose of screening and grading materials. It can be used to realize automatic operation in the assembly line.

| Model | Nominal Size (mm) | Particle Size (mm) | Leaning Angle of Screen(°) | Amplitude (mm) | Layer | Power (Kw) |

| AZ-520 | 500*2000 | 0.074~10 | 0~7° | 4~10 | 1~6 | 2*(0.4~0.75) |

| AZ-525 | 500*2500 | 2*(0.4~0.75) | ||||

| AZ-530 | 500*3000 | 2*(0.4~0.75) | ||||

| AZ-1020 | 1000*2000 | 2*(0.4~0.75) | ||||

| AZ-1025 | 1000*2500 | 2*(0.4~1.1) | ||||

| AZ-1030 | 1000*3000 | 2*(1.1~1.5) | ||||

| AZ-1040 | 1000*4000 | 2*(1.1~1.5) | ||||

| AZ-1225 | 1200*2500 | 2*(1.1~1.5) | ||||

| AZ-1235 | 1200*3500 | 2*(1.1~2.2) | ||||

| AZ-1250 | 1200*5000 | 2*(1.1~2.2) | ||||

| AZ-1535 | 1500*3500 | 2*(1.1~2.2) | ||||

| AZ-1560 | 1500*6000 | 2*(2.2~3.7) | ||||

| AZ-1845 | 1800*4500 | 0.074~15 | 2*(2.2~3.7) | |||

| AZ-2050 | 2000*5000 | 2*(2.2~3.7) | ||||

| AZ-2060 | 2000*6000 | 2*(2.2~3.7) |

Chinese Herbal Medicines Separator

Multi-Layer Separator

New Type Spring Separator

Plastic Grain Separator

Washing Powder Separator

Grape Separator

Air-Cooled Separator

Multi-layer Double Capacity Separator

Double Capacity Separator

Linear vibrating screen is suitable for screening materials which are between 0.74mm and 10mm, water content less than 7%, and no sticky. It is widely used in chemical industry, food, plastic, medicine, metallurgy, glass, building materials, grain, fertilizer, abrasive, ceramics and other industries, for dry powder or granular material screening.

Copyright © Xinxiang AAREAL Machine Co.,Ltd All Rights Reserved Power by SinoArt