E-mail: info@aarealmachine.com

Mobile: +86-156 3736 1027

Fax: +86-373-3988367

WhatsApp: +86-156 3736 1027

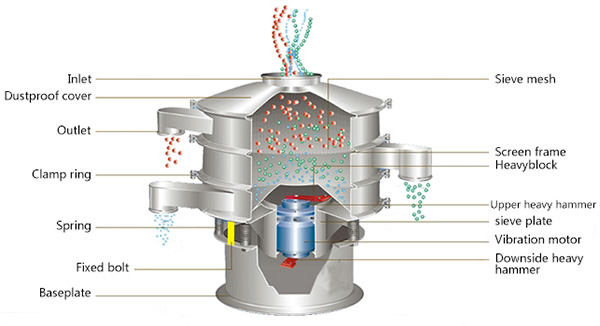

Rotary vibrating screen is also called round separator, circular vibrating sieve, vibro sifter, gyro screen etc.

This kind of screening machine does three-dimensional motion. It can be used in food, medicine, chemical industry, metals, mining, abrasive, ceramics, pigments, coatings, electronic materials, pollution treatment and other industries for wet and dry screening, sieving, grading, classification, filtering, cleaning, de-dusting, impurity removal, lump breaking, quality control and so on.

1. High efficiency, refined design and durability. Any powder and mucus can be sieved.

2. Easy to replace the screen, simple operation and convenience cleaning or washing.

3. The mesh is not blocked. No powder flying. And it can be sieved to 500 mesh or 0.028mm.

4. Impurities and coarse materials are automatically discharged and can be continuously operated.

5. Unique screen flame design. The service life of screen is long. Only 3~5 minutes to replace the screen.

6. Small size, not occupying space, and easy to move.

7. The screen of the machine can reach up to 5 layers, but 3 layers are recommended.

Glue Type Frame

Glue Type Frame |

Bolt Insert Type Frame

Bolt Insert Type Frame |

Dual-screen Frame

Dual-screen Frame |

Single-screen Double-hoop Frame

Single-screen Double-hoop Frame |

Flange Type Frame

Flange Type Frame |

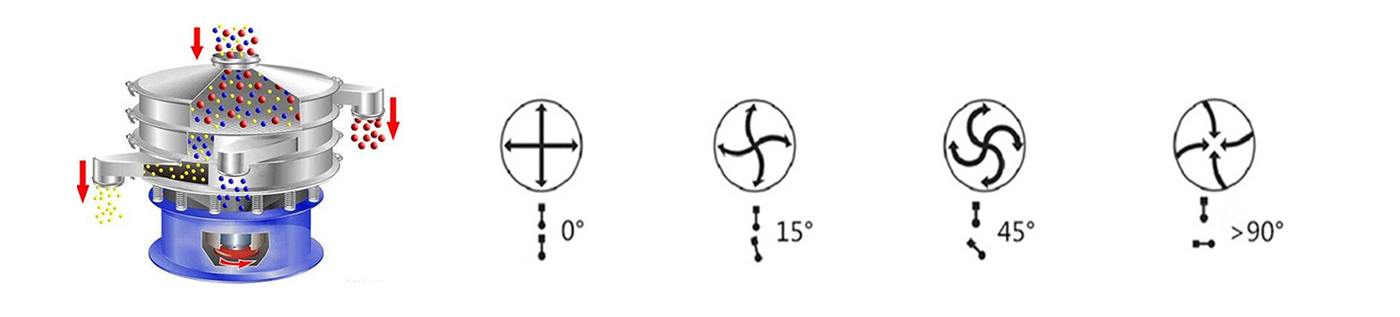

Using the latest type of vertical vibrating motor. The motor produces a horizontal, vertical and oblique vibration of three dimensional vibration, and then passes the vibration to the screen surface.

Changing the space phase angle of the eccentric block (vibration generator) of the motor, it produces different excitation force and then changes the motion direction of the material.

The general characteristics of the vibrator adjustment are described below:

| Gravity Angle | Effects | Main Usage |

| 0° | the raw material flows from the center line to the circumferential direction | Rough classification. Raw materials which are easy to be screened are classified in large number. Coarse grading. |

| 15° | start the vortex motion | Used for general screening |

| 45° | the longest vortex motion | Precision grading. Used for micropowder high condensation and high moisture content of the raw material classification |

| above 90° | raw materials concentrate to the center | special purpose |

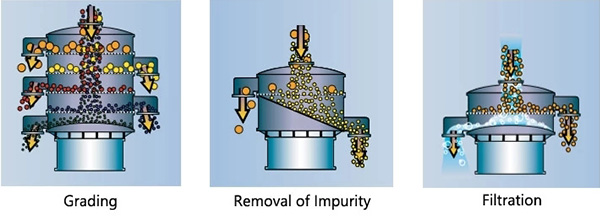

1. fine grading, control particle size range

Separating and screening of different particle sizes solid particle group with narrow particle size range

2. multi-group classification, control particle size range

Separating and screening of solid particle groups with different particle sizes, can be divided into five groups at the same time

3. coarse screening

Separating and screening large particles or ultra fine particles, and achieving high productivity

4. fluffy powder

According to the process requirement, the powder can be fluffy, so that the powder can be mixed into the air, easy to mix other materials

5. filtration and product recycling

It can be used to filter out the large particles in various slurry, or to dehydrate the solid-liquid mixture, or to recycle useful solid particles

6. wastewater purification and water pollution control

It can efficiently recycle useful solid particles and purify water for reuse

| Model | Power (KW) | Screen Surface Diameter (mm) | Effective Screening Area (m2) | Recommended Layers |

| AY-400 | 0.37 | 350 | 0.0962 | 1~3 |

| AY-600 | 0.55 | 550 | 0.2375 | 1~3 |

| AY-800 | 0.75 | 750 | 0.4416 | 1~3 |

| AY-1000 | 1.1 | 920 | 0.6644 | 1~3 |

| AY-1200 | 1.5 | 1120 | 0.9847 | 1~3 |

| AY-1500 | 2.2 | 1420 | 1.5829 | 1~3 |

| AY-1800 | 2.2 | 1720 | 2.3223 | 1~3 |

| AY-2000 | 3.0 | 1920 | 2.89 | 1~3 |

Chemical Industry: PVC, citric acid, electrode materials, resin fertilizer, urea-formaldehyde molding powder, cosmetics, oil paint etc.

Pharmaceutical Industry: lactose, glucose, vitamins, traditional chinese medicine powder, preparations etc.

Metal and Mining Industry: alloy powder, molybdenum powder, stainless steel powder, tungsten powder, aluminum powder, nickel powder, cobalt powder, alumina, glass beads, graphite, kaolin, mineral salts etc.

Abrasive and Coating: aluminum silver paste, powder coating, iron oxide red, laser powder, pearlescent pigment, paper making coating, organic pigment carbon powder etc.

Electronic Materials: fluorescent powder, artificial black lead etc.

Food Industry: wheat bread, bread flour, sugar powder, milk powder, starch, juice, vegetable juice, monosodium glutamate, spices, yeast, seasoning, tofu, ice cream, chocolate powder, potato powder etc.

Pollution Treatment: waste oil and papermaking effluent, effluent from brewery waste water, dyeing and finishing wastewater, activated carbon etc.

Copyright © Xinxiang AAREAL Machine Co.,Ltd All Rights Reserved Power by SinoArt