E-mail: info@aarealmachine.com

Mobile: +86-156 3736 1027

Fax: +86-373-3988367

WhatsApp: +86-156 3736 1027

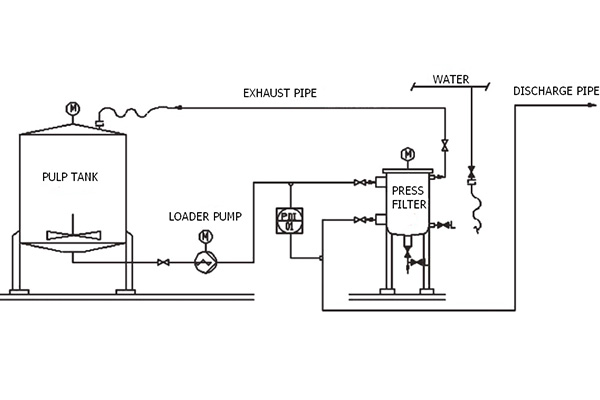

This equipment is a new generation of coating and liquid filtration equipment based on the technology of absorbing similar products from abroad and on the basis of domestic operation practice.

This filtering equipment is mainly used to filter paint glue to ensure the high quality of paint glue and meet the needs of production. It can be used in the paper industry paint preparation system to improve the surface performance quality of the paper industry, and it can also be used for the secondary recovery of paint and oil. , Food industry additives ultra-fine filtration, especially suitable for high-quality, low-energy, high-yield screening of viscous media.

1) All stainless steel production (AISI304 or AISI316)

2) Mechanical continuous cleaning, automatic adjustment of scraper pressure

3) Wedge-shaped slit or microporous screen drum

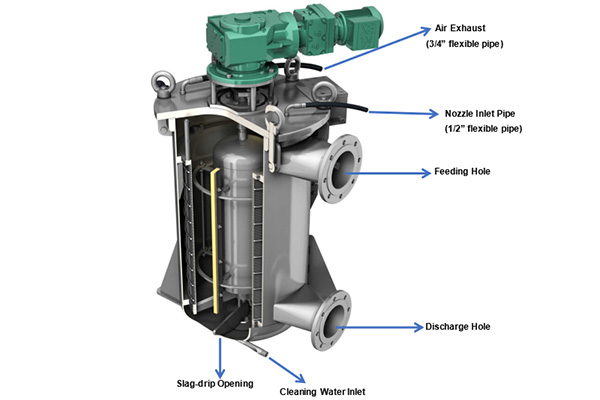

4) Designed with clean nozzle inlet pipe and exhaust pipe

5) Continuous filtration, easy to clean

6) High filtration accuracy

7) The driving power consumes low energy and the use cost is low

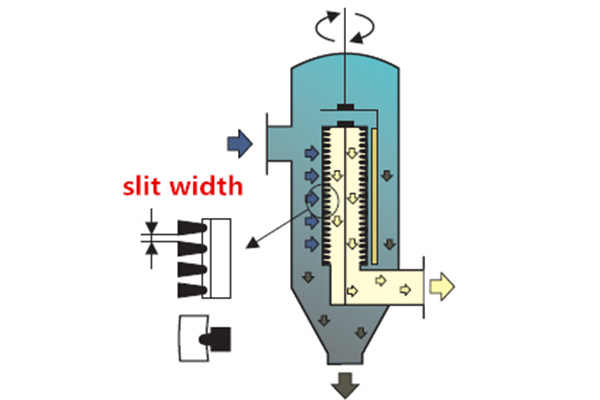

8) The filtering direction is from inside to outside

The forced filter consists of five parts: upper cover, shell, wedge-shaped sieve drum, the rotating drum body and scraper mounted on it, and reducer etc.

The liquid enters the forced filter through the feed port, and is discharged from the discharge port after being filtered by the sieve drum under pressure. The coarse residue remaining on the inner wall of the screen drum is scraped off by the scraper on the rotor, enters the lower part of the filter housing, and is discharged through the slag discharge port.

In order to prevent the precipitated coarse slag from accumulating and forming agglomerates, a special scraper is designed at the lower part of the rotor body to stir and settle the coarse slag in time. The two synthetic material scrapers are controlled by springs to close to the surface of the screen drum and run continuously to ensure the continuous screening capacity of the screen, and to ensure that the screen is at a lower operating pressure under different differential pressures during screening.

AE-20 30 40 50 60 75 100 (Volume)

The width of sieve drum slit are 150μm (100 mesh),125μm (125 mesh),100μm (150 mesh) and 75μm (200 mesh). If you need more compact precision slit width screen drum, it can be customized according to production requirements.

| Model: AE50-1 | Model: AE75-1 | ||||

| Mesh | Aperture (μm) | Designed Flow Rate (l/s) | Mesh | Aperture (μm) | Designed Flow Rate (l/s) |

| 100 | 150 | 28 | 100 | 150 | 42 |

| 125 | 125 | 18 | 125 | 125 | 27 |

| 150 | 100 | 10 | 150 | 100 | 15 |

| 200 | 75 | 5 | 200 | 75 | 6 |

Screw Push Type

Scraper Type

Wedge Screen

Coatings, paints, oils, inks: used in production and secondary recycling;

Paper industry: paint preparation, filter paint, glue, papermaking black liquor filtration, papermaking white water filtration;

High-end ceramics: fine filtration and safety filtration of mud and glaze;

Chemical industry: liquid-solid separation in the process, wastewater filtration;

Food: liquid-solid separation in the process, wastewater filtration;

Solid waste: mud solid waste filtration;

Chinese medicine extraction: filtration of the extract;

Sugar: syrup filtration, juice filtration etc.

Copyright © Xinxiang AAREAL Machine Co.,Ltd All Rights Reserved Power by SinoArt