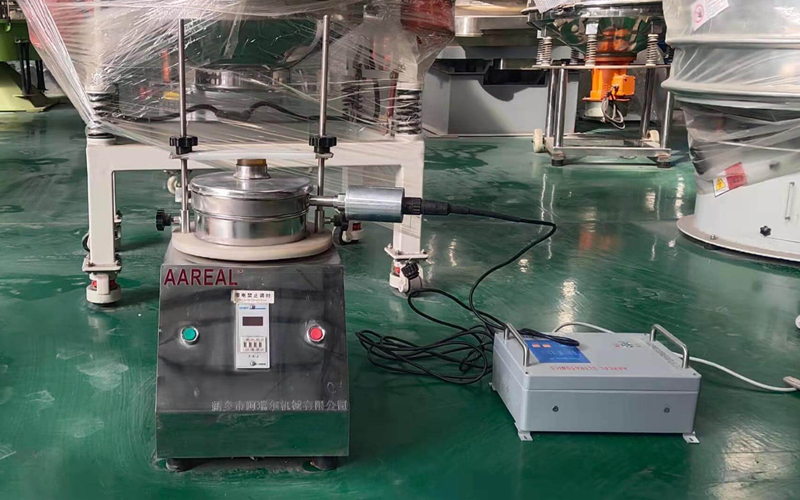

Function and Principle:

AAREAL AT-300 motorized test sieve shaker uses vibration motor as the vibration source. The motor vibration drives the base of the screen machine to vibrate, and then passes through the base to the standard test sieve placed on the base. The material particles smaller than the mesh size of the test sieve are screened into the lower test sieve. Screening layer by layer like this, leaving only the same size of material in each test sieve, the separation of different particle sizes can be achieved and the particle size composition of this material can be determined. Thereby, the material in the test sieve can be effectively sieved, classified and filtered.

Features:

1. High efficiency, compact design and durability, any powder and liquid can be screened.

2. Small size, do not occupy space, easy to move.

3. The sieving machine can be placed up to eight layers of test sieves (including screen bottom), which can accurately separate 2~7 particles at one time.

4. Timing automatic shutdown.

5. Ensure the repeatability of the experiment.

6. Full functions and easy operation.

7. Small noise and light weight.

8. Platform operation, no need to be fixed.

9. Adjustable amplitude.

Application:

It is widely used in food, medicine, chemical, abrasive, paint, mining, metallurgy, geology, ceramics, defense and other industries of scientific research units, laboratories, inspection room, production control for solid, powder, seriflux and other materials of testing, screening, grading, particle size analysis, impurity content analysis and so on.

Installation and Adjustment Instructions:

1. Pre-operation check

I) Whether the machine body is properly placed;

II) Whether the standard test screen is installed in coordination with the standard vibrating sieve shaker;

III) Whether the top and side nuts of the standard vibrating screen are locked;

IV) Whether the machine has any contact with other objects.

2. Matters needing attention in operation

I) Whether there is abnormal noise;

II) Whether there are any other abnormalities.

3. Daily maintenance

I) Before starting: (A) Pay attention to the presence of abnormal murmurs;

(B) Check whether the current is stable;

(C) Check whether the vibration is abnormal or not.

II) After use: Clean up after each use.

Usage:

1. If you need to adjust the vibration amplitude, you can adjust the angle between the upper and lower excitation blocks of the motor in the device to a suitable angle to obtain different exciting forces. Generally do not adjust.

2. Adjust the time according to the screening needs. The first two digits of the time relay in the middle of the front panel of the standard vibrating screen are minutes, and the last two digits are seconds. The timing can be adjusted as needed within 0-99 minutes and 59 seconds.

3. The standard test sieve used in the standard vibrating screen machine, the bottom layer is placed on the sieve bottom (non-porous screen), and the top is placed on the sieve cover. Between the sieve bottom and cover, from top to bottom, according to the requirements of the screening size section, 1~7 layers of test sieves can be placed from coarse to fine. The material to be sieved is placed on the top layer (also the coarsest screen mesh).

4. Place the standard test sieves in the device and lock the nuts on the top and sides. The method is as follows: first, loosen the four locking nuts on the top and both sides of the standard vibrating screen, so that the two vertical columns on both sides can fall freely, falling on the standard test sieve that has been placed, then lock the locking nuts on both sides, and finally lock the two nuts on the top of the screen machine. Note: nuts on top and sides must be locked.

5. After doing the above steps, open the green button on the front panel of the standard vibrating screen machine, and after a period of time screening, the screen machine will stop automatically when the time is over, or you can press the red button to end the screening. At the end of the screening, you can screen out the materials of the multiple size segments you need.

Remember!!!

Do not debug with power. Adjust it after shutdown.

Technical Parameters:

| NO. | Name | Value | Unit |

| 1 | Sieve Diameter | Ø200, Ø100, Ø75 | mm |

| 2 | Particle Size | 0.025~3 | mm |

| 3 | Motor Power | 0.125 | Kw |

| 4 | Noise | <50 | dB |

| 5 | Amplitude | 0~3 | Mm |

| 6 | Vibration Frequency | 1420 | times/min |

| 7 | Overall Dimensions | 400*300*300+N*50 | L*W*H |

| 8 | Power Supply | 220; 50 | V; HZ |

| 9 | Total Weight | 30 | Kg |

Copyright © Xinxiang AAREAL Machine Co.,Ltd All Rights Reserved Power by SinoArt